· To study PID design.

Theory:

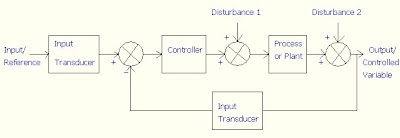

There are several technique available to the control system engineers to design a suitable controller. One of them widely used is the proportional plus integral plus derivative (PID) controller, which has the transfer function:

Kp=Propotional gain.

KI=Integral gain.

KD=Derivative gain.

MatLab Code:

clear all;

close all;

figure;

num=1;

den=[1 10 20];

sys=tf(num,den);

step(sys);

grid

Title('Step Response for the Open Loop System');

xlabel('Time')

ylabel('Speed');

figure;

num=50;

den=[1 10 70];

sys=tf(num,den);

step(sys);

hold on;

num=100;

den=[1 10 120];

sys=tf(num,den);

step(sys);

hold on;

num=150;

den=[1 10 170];

sys=tf(num,den);

step(sys);

grid

Title('Step Response for Proportional Controller Closed Loop System');

xlabel('Time')

ylabel('Speed');

figure;

num=[25 12];

den=[1 10 45 12];

sys=tf(num,den);

step(sys);

hold on;

num=[50 48];

den=[1 10 70 48];

sys=tf(num,den);

step(sys);

hold on;

num=[75 108];

den=[1 10 95 108];

sys=tf(num,den);

step(sys);

hold on;

num=[100 192];

den=[1 10 120 192];

sys=tf(num,den);

step(sys);

grid

Title('Step Response for Proportional Integral Controller Closed Loop System');

xlabel('Time')

ylabel('Speed');

figure;

num=[5 20];

den=[1 15 40];

sys=tf(num,den);

step(sys);

hold on;

num=[10 40];

den=[1 20 60];

sys=tf(num,den);

step(sys);

hold on;

num=[15 60];

den=[1 25 80];

sys=tf(num,den);

step(sys);

hold on;

num=[20 80];

den=[1 30 100];

sys=tf(num,den);

step(sys);

grid

Title('Step Response for Proportional Derivative Controller Closed Loop System');

xlabel('Time')

ylabel('Speed');

figure;

num=[5 25 50];

den=[1 15 45 50];

sys=tf(num,den);

step(sys);

hold on;

num=[10 50 100];

den=[1 20 70 100];

sys=tf(num,den);

step(sys);

hold on;

num=[15 75 150];

den=[1 25 95 150];

sys=tf(num,den);

step(sys);

hold on;

num=[20 100 200];

den=[1 30 120 200];

sys=tf(num,den);

step(sys);

grid

Title('Step Response for Proportional Integral Derivative(PID) Controller Closed Loop System');

xlabel('Time')

ylabel('Speed');

MatLab Data:

Report:

Give the inferences on the effects of proportional, integral and derivative control upon system performances such as rise time, overshoot, settling time and steady state error.

Is it possible to redesign the above PID controller with another set of Kp, KI and KD? If possible, design the controller.

Yes, it is possible to redesign the PID controller with another set of Kp, KI and KD.

Design of the PID controller:

MatLab Code:

clear all;

close all;

num=[10 100 200];

den=[1 20 120 200];

sys=tf(num,den);

step(sys);

hold on;

num=[10 100 175];

den=[1 20 120 175];

sys=tf(num,den);

step(sys);

hold on;

num=[7 50 90];

den=[1 17 70 90];

sys=tf(num,den);

step(sys);

Grid

title('Step Response for Redesign the PID Controller Closed Loop System');

xlabel('Time')

ylabel('Speed');

| Kp | KD | KI | Rise Time (Sec) | Overshoot (%) | Settling Time (Sec) | Steady State Error (%) |

| 100 100 50 | 10 10 7 | 200 175 90 | 0.2194 0.2304 0.5695 | 1.030 0.529 0.829 | 0.395 0.543 1.080 | 0.0 0.0 0.0 |

These designs fulfill our system requirments. So these can be a useful alternative of the given design of the system. The proposed design will be more economical and simple.